Technical Services/ TECHNICAL

Products

Contact Us

BoZhong (Shandong) Industrial Equipment Co., Ltd. | Part of the Atlas Copco Group

Address: No.50# YiDa Road, NanDing Town, Economic Development Zone, ZiBo, ShanDong, China

Tel: +86-533-2530388

Website: en.zbbz.com

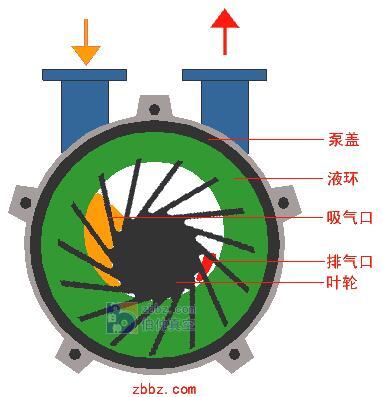

Working principle of water (liquid) ring vacuum pump

Water ring vacuum pump (referred to as the water ring pump) is a crude vacuum pump, which can get the ultimate vacuum of 2000 ~ 4000Pa, and up to 270~670Pa if connecting air injectors in series. Water ring vacuum pump can also be used as compressors, known as water ring compressors, which belong to the low pressure compressor, with the pressure range of1~2×105Pagauge pressure.

Water ring pump was originally used as a self-priming pump, and then gradually used in petroleum, chemistry, machinery, mining, light industry, medicine, food and many other industrial sectors. Water ring pumps have been widely used in many process procedures of industrial production, such as vacuum filtering, vacuum water diversion, vacuum feeding, vacuum evaporation, vacuum concentration, vacuum damping and vacuum degassing. Due to the leap development of vacuum application technology, the water ring pump has attracted much attentions in the rough vacuum. Due to gas compression of the water ring pump is isothermal, so that flammable and explosive gas can be extracted; moreover, it can pump air containing dust and water; therefore, water ring pumps are used more and more widely.

Water ring vacuum pumps can also use other suitable liquid as working fluid, and they are collectively called as liquid ring vacuum pumps regardless of their working. Water ring vacuum pump is a pump most commonly and widely used.

|

|

|

|

|

Such as:in the pump body with the amount of water as working fluid. When the impeller rotates clockwise according to the diagram, the water was thrown around the impeller, due to centrifugal force, decided to form a water pump cavity such as the shape similar to the thickness of the closed circle. The next part of the water ring coincided with the inner surface of the impeller wheel tangent, the water ring the inner surface of the top blades and just contact (actually there are some inserting depth for blades in the water rings). A crescent shaped space between the impeller wheel and the water ring in the interface, and this space has been divided into several small impeller blades and blade number equal if. If taking the lower part 0°of the impeller as a starting point, then the small cavity’s volume will change from small to large in the leading 180°of rotation; And connect with suction ports on the ends. At this time, the gas is inhaled, the small cavity is isolated with the suction ports at the end of the suction. When the impeller continuously rotates, the small cavity changes from big to small, let the gas be compressed; when the small cavity and the air outlet are through, gas will be discharged out of the pump. To sum up, the water ring pump realizes inspiration, compression and exhaust by change in the volume of pump chambers; so that it belongs to the variable volume type vacuum pump. |

By comparing other types of mechanical vacuum pumps, the water ring pump has the following advantages: .Simple structure and not high manufacturing accuracy; easy to be manufactured. .Compact structure and higher pump rpm; generally connected with motors directly, without deceleration device. .Therefore, pumps in a small structural size can get a large amount of exhaust, covering small area. .The compressed gas is essentially isothermal, that is, the temperature of air during the compressed process is very small. .Since there is no metal friction surface in the pump cavity, it doesn’t need to lubricate the pump, and wear little. Sealing between rotating parts and fixed parts can be done directly by water sealing. .Breathing evenly, stable and reliable work, simple operation and convenient maintenance.

|

However, water ring pump also has its disadvantages:

. Efficiency is low, generally in about 30%, better up to 50%.

.Vacuum degree is low, this is not only due to structural constraints, but also the limitation of work fluid saturated vapor pressure. If water is used as working fluid, the ultimate pressure can only reach 2000~4000Pa, or else, the ultimate pressure can be up to 130Pa if taking oil as working fluid.

In short, because the gas compression in the water ring pump is isothermal, so it can be pumped out the flammable and explosive gases. Gas containing dust, condensable gas and gas water mixture can be pumped out because there are no exhaust valves and friction surfaces. With these outstanding features, water ring vacuum pumps are still widely used although they are inefficient.

Cavitation of liquid ring vacuum pump

When liquid ring vacuum pump is working at a certain temperature, if the liquid pressure at the low pressure is lower than the vapor pressure under the temperature (i.e. saturated vapor pressure), liquid is vaporized to generate bubbles, which will be ruptured if they enter the high-pressure zone along with the liquid; surrounding liquid quickly fill the bubble cavities, and generate hydraulic impacts. These bubbles’ generation, development and rupture phenomenon are called cavitation.

In the working process of the liquid ring vacuum pump, the absolute pressure of the suction area is consistent with the absolute pressure of the pumped system. That is to say, the higher the vacuum degree of the pumped system is, the higher the vacuum degree of the suction area is.

The liquid ring vacuum pump has liquid saturated steam as the working medium. Each liquid has a corresponding temperature in a certain pressure. When the saturated steam suction area is close to the absolute pressure of the liquid pressure, the liquid is close to the boiling state. Then, in the suction working liquid surface area will produce a large number of bubbles. The working fluid vapor liquid produced in the working chamber will occupy part of the work space, inspiratory capacity of external pump will decrease. When the pressure reaches the saturated steam suction area of working fluid pressure, can be considered the working chamber is filled with a working fluid vapor, the foreign pump suction capability is close to zero, and cavitation of this pump is most serious.

If the working fluid is water, the higher is the water temperature, the more the pumping performance of the pump will be reduced. The effect of water temperature on the pumping rate of the water ring vacuum pump can refer to page 72 of this manual.

Liquid ring pump cavitation damage and centrifugal pump cavitation damage is the same principle, in bubble generation and the site of rupture and metal surface appeared pitting phenomenon, serious will appear cellular damage. If vacuum pump impeller in the cavitation area has larger residual stress, but also will cause stress release crack.

Due to pump cavitation, bubbles in the high-pressure area continuous burst, and with strong water hammer, noise and vibration are generated. Can hear sounds like the explosion beans. Experimental results show that the cavitation induced vibration frequency range is 600 ~ 25000Hz at pressures up to 49MPa.

If the bubble is broken on the surface of the metal, metal surface will suffer strong and continuous water impact, and then appear pitting; metal grains loose and spalling, and then form honeycomb and even perforation. Cavitation damage in addition to the mechanical action, accompanied by electrolysis, chemical corrosion and so on the many kinds of complex role. Actual damage shows pump flow components of cavitation damage of parts is the disappearance of the bubble.

Prevention measures and elimination methods of cavitation

Liquid ring vacuum pump in the cavitation state for a long time, will cause the pump noise, vibration, or even damage to the pump, so should try to avoid the liquid ring vacuum pump in cavitation state, can work through the following methods:

1. Reduce temperature of the working fluid

Under the premise of the working point of the liquid ring vacuum pump to be fixed values, the temperature of the working fluid can be reduced to prevent cavitation.

2. Let the vacuum pump operate in a safe area, and improve the accuracy of type selection

This requirement in the selection stage, the choice of liquid ring vacuum pump suction pressure and working fluid temperature to avoid the liquid ring pump is prone to cavitation pressure range.

3. Install cavitation protection pipeline or one-way valves

Produced in the process of cavitation bubble burst in the compression process, from the outside into high pressure gas can replenish due to rupture of the bubble and the emergence of space, which can greatly reduce cavitation damage to the pump and reduce the cavitation caused by noise and vibration.

2BE1 and 2BV have a cavitation protection interface. When the pump appears cavitation phenomenon, non-condensing gas can be filled from the cavitation protection interface on the pump exhaust side, to eliminate cavitation noise, and greatly reduce the damage of cavitation to the pump.

4.Equipped with atmospheric jet

Such as liquid ring vacuum pump with an air ejector, the liquid ring pump is not prone to cavitation phenomenon.

5. Liquid is used as the working fluid with lower saturated vapor pressure.

6. The pump impellers and discs adopt materials with a strong anti-cavitation ability.